What Is Polyethylene Rope, and Why is UHMWPE So Much Stronger?

Estimated 0 min read

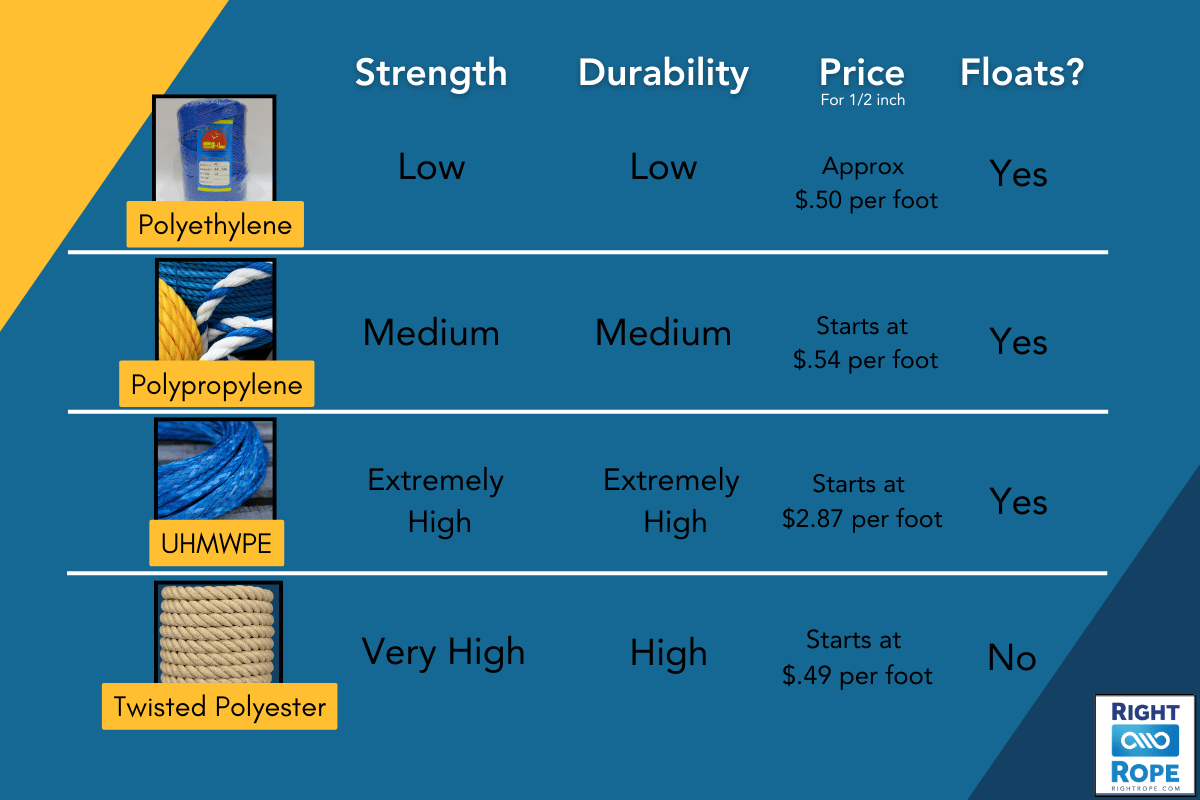

Polyethylene rope is one of those materials that shows up in a lot of recreational uses—from pool ropes to golf course barriers, trail ropes and more. It’s affordable, lightweight, and easy to use. But in recent years, better ropes have become less expensive, and the number of options has increased. While polyethylene has its place, it’s worth taking a closer look at a couple alternatives: Twisted Polyester, UHMWPE (Ultra-High Molecular Weight Polyethylene) and Polypropylene. Each offers distinct advantages that make them better investments for a lot of jobs. Let’s dive into what polyethylene rope is, how it’s made, and why upgrading to polyester, UHMWPE, or polypropylene might be the smarter choice.

What Is Polyethylene Rope?

Polyethylene rope is made from polyethylene plastic, one of the most common plastics used today. This material is known for its flexibility, water resistance, and lightweight properties. Polyethylene rope is often hollow-braided, making it easy to splice and handle. You’ll find it in applications like:

- General-purpose tying

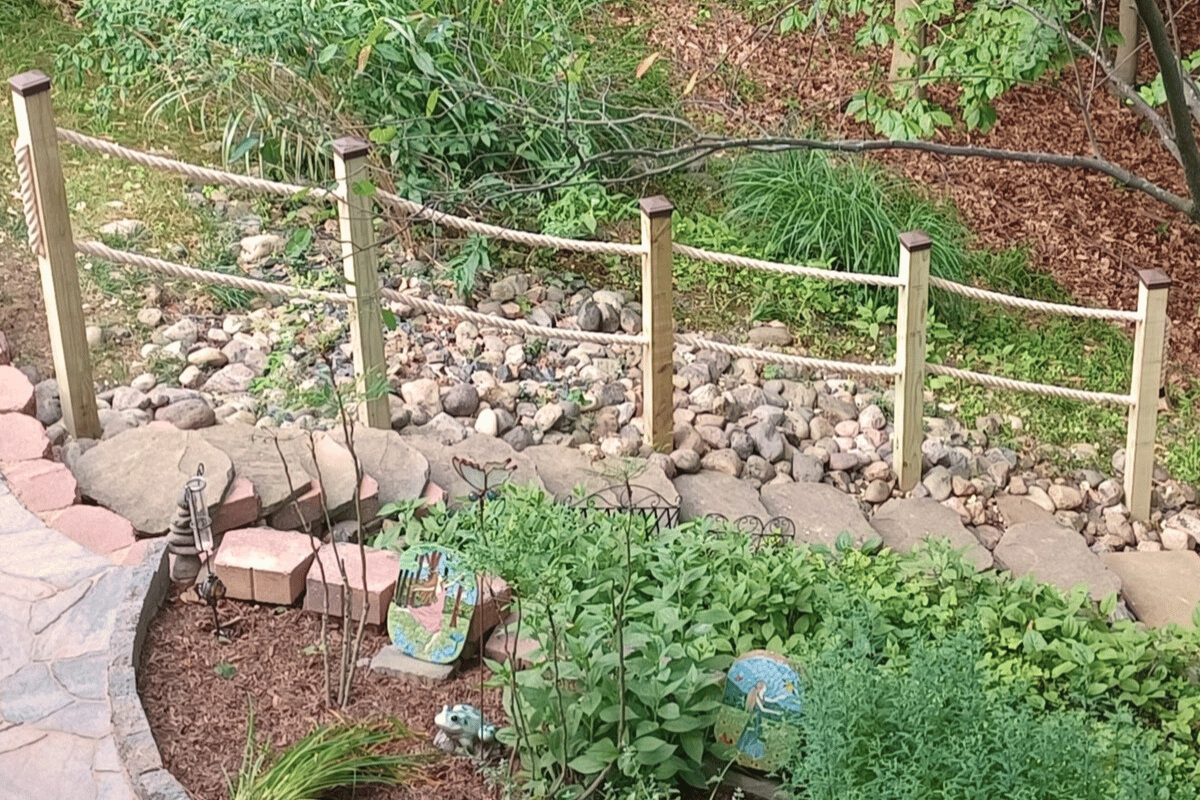

- Golf course barriers

- Trail guides

- Marine use, pool ropes (it floats)

- Temporary rigging

On the surface, polyethylene rope sounds like a no-brainer: it’s cheap, it floats, and it gets the job done for basic tasks. But once you start pushing its limits, its shortcomings become clear—it’s not a very strong rope, has poor abrasion resistance, and it can’t endure heat or long-term direct sunlight. There are several better options that RightRope offers for a similar price.

How Polyethylene Rope Is Made

Polyethylene rope starts with small plastic pellets that are melted and extruded into fibers. These fibers are braided or twisted to form the rope. Additives like UV stabilizers or reflective tracers can be included to improve performance.

While the process creates a functional product, it doesn’t result in a rope built for heavy-duty or long-term use. Over time, polyethylene rope is prone to wear and tear, and it won’t last like polyester or even polypropylene will.

Why UHMWPE Rope Is a Superior Option

If polyethylene rope is the baseline, UHMWPE is the top-tier upgrade. Ultra-High Molecular Weight Polyethylene takes the same basic material and processes it differently to create a rope that’s stronger, tougher, and far more reliable. Specifically UHMWPE fibers are spun to have much longer molecular chains than polyethlyne.

Advantages of UHMWPE Rope

- Extreme Strength: UHMWPE is incredibly strong—15 times stronger than steel by weight. It’s perfect for applications where reliability is critical, like winch lines, rigging, or sailing.

- Durability: While polyethylene rope wears down over time, UHMWPE stands up to abrasion, heavy loads, and harsh conditions.

- Lightweight and Floats: Like polyethylene, UHMWPE floats on water, but with significantly better performance.

- High Performance in Tough Conditions: Whether you’re dealing with extreme weather, rough surfaces, or high tension, UHMWPE handles it all without breaking down.

When to Choose UHMWPE

If you need rope for demanding jobs where failure isn’t an option—think towing, industrial rigging, or marine applications—UHMWPE is the way to go. Yes, it costs more upfront, but its strength and durability make it a better long-term investment.

A Budget-Friendly Alternative: Polypropylene Rope

What if UHMWPE is overkill for your needs or out of your price range? Enter polypropylene rope. This rope offers many of the same advantages as polyethylene but at an even lower cost—and it outperforms polyethylene in a lot of ways.

Advantages of Polypropylene Rope

- Affordable: Polypropylene rope is one of the most cost-effective ropes on the market, making it ideal for projects where you don’t need industrial-grade performance.

- Lightweight and Floats: Like polyethylene, polypropylene floats on water, making it a great choice for marine use, pool markers, and other water-related tasks.

- Chemical and Rot Resistance: Polypropylene resists exposure to chemicals, rot, and mildew, just like polyethylene, but tends to hold up better over time.

- Versatile: Whether you’re marking pool lanes, trail boundaries, or doing general-purpose work, polypropylene rope is a reliable option that won’t break the bank.

Twisted Polyester Rope: The Perfect Choice for Strength and Durability

If you’re looking for a rope that combines strength, durability, and affordability, polyester rope is a standout choice. While polyethylene and polypropylene ropes have their merits, polyester ropes offer a significant upgrade in quality and performance, at a comparable cost. Whether you’re working on demanding projects or just need a reliable rope for everyday use, polyester rope delivers exceptional value.

Why Choose Polyester Rope?

Polyester rope is built to handle more demanding tasks than polyethylene or polypropylene ropes can manage. It offers a superior blend of strength, durability, and longevity, making it the go-to choice for professionals and DIYers alike. Here’s why:

- High Strength: Polyester rope boasts excellent tensile strength, making it suitable for handling heavy loads or tasks that require extra reliability.

- Low Stretch: Unlike polyethylene and polypropylene, which can stretch under tension, polyester rope maintains a low stretch profile, ensuring consistent performance under load.

- Abrasion Resistant: The polyester outer fibers are tough and stand up to wear and tear, even when dragged over rough surfaces.

- UV Resistant: Prolonged exposure to sunlight can weaken many ropes, but polyester is highly resistant to UV damage, making it ideal for outdoor use.

- Best Value: Despite its superior quality, polyester rope costs about the same as polyethylene or polypropylene, making it an economical choice for a better product.

Where Polyester Shines

Polyester rope excels in tasks where strength, durability, and low stretch are essential. Some of its common uses include:

- Tree Work: Polyester ropes are a favorite for arborists thanks to their strength, abrasion resistance, and ability to handle demanding jobs like rigging and bull lines.

- Utility Work: Polyester ropes perform well in construction, heavy lifting, and other rugged applications.

- Battle Ropes: Its durability and weight make it an excellent choice for fitness ropes.

- Marine and Outdoor Use: While polyester rope doesn’t float, it resists rot, mildew, and petroleum products, making it a long-lasting option in wet or harsh conditions.

Check out our Twisted Polyester for a beautiful natural looking rope, our Poly combo for a slightly more affordable option, or our Double Braid Polyester for a very strong premium rope that won’t break the bank.

A Key Tradeoff With Polyester: It Doesn’t Float

One thing to keep in mind is that polyester rope does not float on water. If buoyancy is critical—say, for marine applications like buoy lines or dock lines—you’re better off with polypropylene rope. For jobs where strength and abrasion resistance take priority, however, polyester is the superior option.

When Should You Skip Polyethylene Rope?

Polyethylene rope is fine for temporary or light-duty use, but it’s not built to last under challenging conditions. Here are a few scenarios where upgrading makes more sense:

- Heavy Loads: Polyethylene rope lacks the strength of UHMWPE or even polypropylene. If you’re hauling, lifting, or pulling, it won’t hold up.

- Harsh Environments: Sun, friction, and heavy use wear out polyethylene faster than other materials.

- Marine Applications: While polyethylene floats, its overall durability in marine settings can’t compare to UHMWPE or polypropylene.

The Bottom Line: Make the Upgrade

Polyethylene rope has its place, but it’s not always the best choice. If you’re looking for performance and reliability, UHMWPE is unmatched. For general-purpose use on a budget, polypropylene or twisted polyester is usually a smarter investment than polyethylene.

Whatever your needs, feel free to reach out to us if you need help deciding on the Right Rope! We're always happy to talk to our customers.