Twisted Nylon Rope

Our double braid nylon rope is made in the USA. Double braid nylon is the right choice for any application where some stretch is required to mitigate the chances of rope failure or you need a very strong, durable rope with the elasticity to be able to withstand shock loading. Great for anchor / dock lines and towing.

These ropes are made by expert rope makers using modern braiding equipment and meets or exceeds the standards set by the Cordage Institute specifications for high-performance ropes.

Double-braid is typically the strongest construction of rope and has a braided inner core and a braided outer jacket. This rope construction is torque-free and will not hockle or kink, and can be easily spliced. Nylon has excellent abrasion resistance and ultraviolet degradation protection. Our premium double braid nylon ropes are also resistant to rot, mildew, marine growth, chemicals and petroleum products. These high-strength ropes are soft, flexible, and are easy to handle.

If using this rope to create a custom dock line or mooring line to secure the eye of the rope to a cleat on your boat, we recommend the following minimum eye-splice sizing guidance (be sure to know the size of your cleat before making a custom order to ensure your eye will fit over your cleat).

General / standard eye-splice sizing guidance:

There are some differences between double braid nylon and double braid polyester.

Nylon is slightly stronger, and much more elastic or given to stretch. This can be an advantage or disadvantage depending on your application. If you need a high-stretch rope go with this nylon.

Our double-braid nylon has a melting point of about 490 degrees Fahrenheit, and starts to lose strength at around 240 degrees Fahrenheit. Nylon rope can shrink around 10% when wet and also lose around 10% of its strength. Please take this into consideration when ordering.

Polyester has better abrasion resistance and UV resistance than nylon, but much less elasticity. If you need a low stretch, durable rope, go with Double Braid Polyester, instead of this nylon.

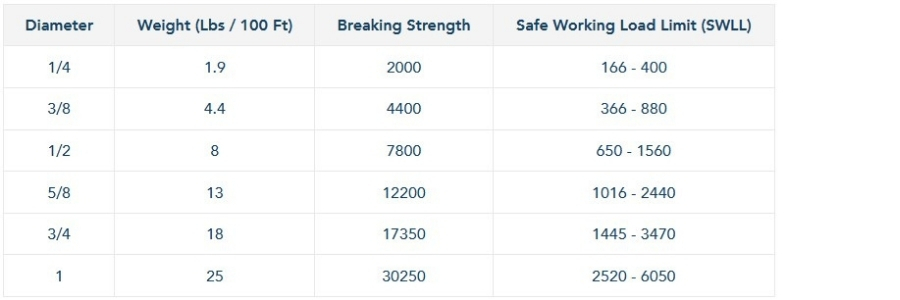

| Diameter | Weight (Lbs / 100 Ft) | Breaking Strength | Safe Working Load Limit (SWLL) |

|---|---|---|---|

| 1/4 | 1.9 | 2000 | 166 - 400 |

| 3/8 | 4.4 | 4400 | 366 - 880 |

| 1/2 | 8 | 7800 | 650 - 1560 |

| 5/8 | 13 | 12200 | 1016 - 2440 |

| 3/4 | 18 | 17350 | 1445 - 3470 |

| 1 | 25 | 30250 | 2520 - 6050 |

Strength

Stretch

Durability

Abrasion Resistance

Rot Resistance

Sunlight / UV Resistance

Petroleum Resistance

Mold / Mildew Resistance

Loading results...