What Is HMPE Rope And What Makes HMPE So Strong?

Estimated 0 min read

High-Modulus Polyethylene, better known as HMPE rope, has become one of the most in-demand synthetic ropes across industries. From arborists and utility workers to sailors, winch operators, and off-road enthusiasts, everyone wants a rope that’s lightweight, floats on water, and still has stronger-than-steel performance. And that’s exactly what HMPE is.

In this blog, we’ll break down exactly what HMPE rope is, why it’s so strong, how it compares to other ropes, and where it actually makes sense to use it. We’ll also cover popular questions people ask about HMPE, and explain things in plain English. No guesswork, no marketing fluff.

Let’s get into it.

What Is HMPE Rope?

HMPE stands for High-Modulus Polyethylene. It’s an ultra-high-strength synthetic fiber created by stretching polyethylene molecules until they’re long, straight, and extremely aligned. This alignment gives the rope its huge strength-to-weight ratio. You may also hear HMPE referred to as:

- UHMWPE rope (Ultra-High Molecular Weight Polyethylene)

- HPPE rope (High-Performance Polyethylene)

- Dyneema rope (rope made from Dyneema brand HMPE)

- Spectra rope (another brand name)

All HMPE ropes fall into the same category. They’re made from gel-spun polyethylene fibers that are drawn and heat-set to create a rope that’s astonishingly strong for how little it weighs.

Why does this matter?

The molecular alignment causes HMPE fibers to share the load evenly, resisting stretching and breaking. It may not sound that important but the breaking strength of HMPE is typically about 10x that of a similar diameter polyethylene rope. HMPE rope is one of the strongest synthetic ropes ever made, up to 15x stronger than steel cable by weight.

Shop HMPE Now

How Do They Make HMPE Rope?

HMPE is typically gel-spun. The process of rope making typically starts with a UHMWPE powder being mixed with oil or decalin, and precisely heated to make a gel solution. The gel solution of HMPE is extruded through a spinneret to form filaments, then individual filaments of HMPE are stretched to many times their original length.

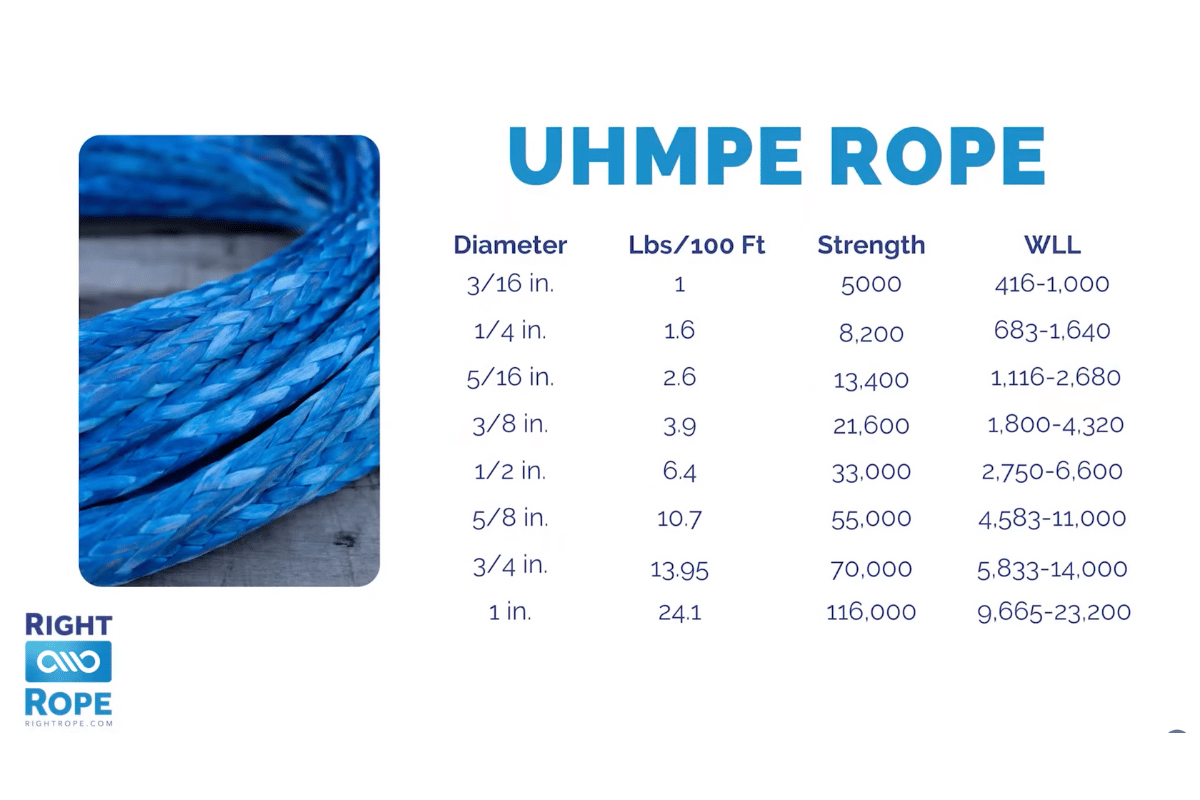

This stretching process is what makes the filaments so strong, as the long polymer chains become oriented in all the same direction. This can result in parallel orientation of polymer chains at higher than 95%, and a level of crystallinity of up to 75%. These filaments are then twisted into strands, and then braided into rope. The resulting rope is incredibly strong and lightweight, so strong in fact that a piece of ½ inch diameter HMPE rope has a minimum breaking strength of up to 33,000 lbs—the equivalent of 7 pick up trucks.

What Are The Qualities of HMPE?

How can something so light be so tough? HMPE’s strength comes from a combination of its molecular structure and manufacturing process. Here are the qualities of HMPE, broken down.

1. Extremely long and aligned polymer chains

The fibers are made from polyethylene molecules stretched until they’re nearly straight. This gives HMPE rope huge tensile strength, low stretch under load, high modulus (a fancy word for stiffness), and superior fatigue resistance.

2. Gel-spun manufacturing

Gel spinning creates fibers that are stronger and more uniform than typical extrusion methods. This is why HMPE ropes outperform nearly every other synthetic rope, including nylon, polypropylene, and polyester.

3. Low specific gravity (it floats)

HMPE fibers are lighter than water. This doesn’t make it stronger, but it’s why HMPE rope floats. And because it’s synthetic, it doesn’t absorb water at all—pretty handy for marine uses like yacht dock lines or really big anchor lines.

4. High abrasion resistance

Even under heavy friction, HMPE fibers resist wear, making them ideal for winches, pulling rope applications, rigging, and industrial lifting.

5. UV and chemical resistance

HMPE naturally resists UV rays, most chemicals, moisture and rot. That's why HMPE rope lasts longer outside than many natural or synthetic ropes.

Shop HMPE Now

Is HMPE Rope the Same as Dyneema?

People search this one a lot:

“HMPE vs Dyneema—what’s the difference?”

Here’s the simple answer:

Dyneema is a brand of HMPE produced by DSM. Spectra is another brand of HMPE made by Honeywell.

All Dyneema ropes are HMPE, but not all HMPE ropes are Dyneema. It’s similar to how Kleenex has become synonymous with facial tissue.

Common Uses: What Is HMPE Rope Good For?

HMPE rope is used anywhere you need high strength, low stretch, and minimal weight. Here are the most common applications:

1. Winch lines and recovery rope

Because HMPE is stronger and lighter than steel, it makes an excellent synthetic winch line.

2. Sailing and marine rigging

HMPE floats, resists saltwater, and has low stretch, making it perfect for halyards, sheets, mooring lines and more.

3. Utility and overhead pulling

HMPE is extremely popular for wire pulling, cable installation, line stringing and overhead transmission work. The low stretch and high efficiency reduce fatigue and line breaks.

4. Industrial lifting

Because HMPE is lightweight and strong, it replaces steel in some lifting sling applications.

5. Off-road towing and recovery

4×4 and UTV drivers like HMPE because it won’t store as much kinetic energy as a steel line, and it’s much easier to handle.

How Strong Is HMPE Rope Compared to Other Ropes?

Here’s the comparison many people are searching for:

HMPE rope vs steel cable

Pound-for-pound, HMPE is up to 15x stronger than steel cable.

HMPE vs polyester rope

HMPE is stronger, lighter, and lower stretch. Polyester is more heat-resistant and more UV resistant.

HMPE vs nylon rope

Nylon stretches a lot (up to 30%), which is good for shock absorption. HMPE barely stretches at all, which is better for static rigging and winching.

HMPE vs polypropylene rope

There’s no comparison, HMPE is extremely strong and abrasion-resistant, while polypropylene is inexpensive and weaker.

Buy HMPE Rope

Does HMPE Rope Stretch?

One of the defining traits of HMPE rope is very low stretch, often around 1% at working load.

Low stretch means predictable performance under load.

This is why HMPE rope is used for winching, rigging, and precision lifting.

Does HMPE Rope Melt?

Yes, HMPE has a relatively low melting point, around 130 to 136°C (266–277°F).

HMPE can lose strength from heat generated by friction.

For example if you are:

- Running HMPE over a fast-moving capstan

- Dragging it across dry, abrasive surfaces

- Heat buildup inside winch drums

For high-heat applications, polyester rope is usually a better option.

Does HMPE Float?

Yes. HMPE rope floats because it’s less dense than water. This makes it popular for marine use, water rescue, mooring lines, anchor lines, yacht ropes, and oil tankers.

Is HMPE Rope Abrasion-Resistant?

Extremely. HMPE is known for high abrasion resistance on a molecular level. However, it can be vulnerable to sharp edges, especially under load.

For the best durability, many HMPE ropes are covered with a protective jacket. Our UHMWPE rope has a urethane coating.

What About UV Resistance?

HMPE has pretty good UV resistance, better than polypropylene. This makes HMPE a great choice for long-term outdoor exposure.

How Long Does HMPE Rope Last?

Depending on use, HMPE rope often lasts longer than traditional synthetic ropes in industrial applications.

Factors that affect life span include:

- UV exposure

- Abrasion

- Heat

- Load cycles

- Chemical exposure

For most users, HMPE rope lasts several years with proper care.

Popular Questions About HMPE Rope (And Straightforward Answers)

What does HMPE stand for?

High-Modulus Polyethylene.

Is HMPE the same as Dyneema?

Dyneema is a brand of HMPE. They are in the same family.

Is HMPE stronger than steel?

Pound for pound, yes.

Can you splice HMPE rope?

Yes, HMPE is easily spliceable, especially in 12-strand form.

Is HMPE rope good for winches?

Yes, it’s the most popular winch line material today.

Does HMPE rope rot?

No. HMPE has excellent resistance to rot, mildew, and moisture.

Does HMPE rope float?

Yes.

Does HMPE melt easily?

It has a relatively low melting point compared to polyester or nylon.

Can HMPE replace steel cable?

In many cases, yes, especially in winching and pulling applications.

Why Choose HMPE Rope?

To sum it up, HMPE rope offers:

- Incredible strength-to-weight ratio

- Low stretch

- High abrasion resistance

- UV and chemical resistance

- Floatability

- Easy handling

Whether you’re lifting, towing, sailing, rigging, or pulling, HMPE rope is one of the strongest and most reliable choices you can make.

Final Thoughts: Is HMPE Rope Worth It?

If you need a rope that’s tough, lightweight, and built for serious work, HMPE is about as good as it gets. It’s stronger than almost every synthetic rope on the market, and in many cases it outperforms steel cable, without the weight, rust, or recoil danger.

It’s not the cheapest rope out there, but it’s one of the best long-term investments if you want reliability, safety, and performance.

HMPE rope is an impressive material, and once you use it, you’ll understand why so many professionals won’t use anything else.