The Ultimate Rope Inspection Checklist: When You Need To Replace Your Rope

Estimated 0 min read

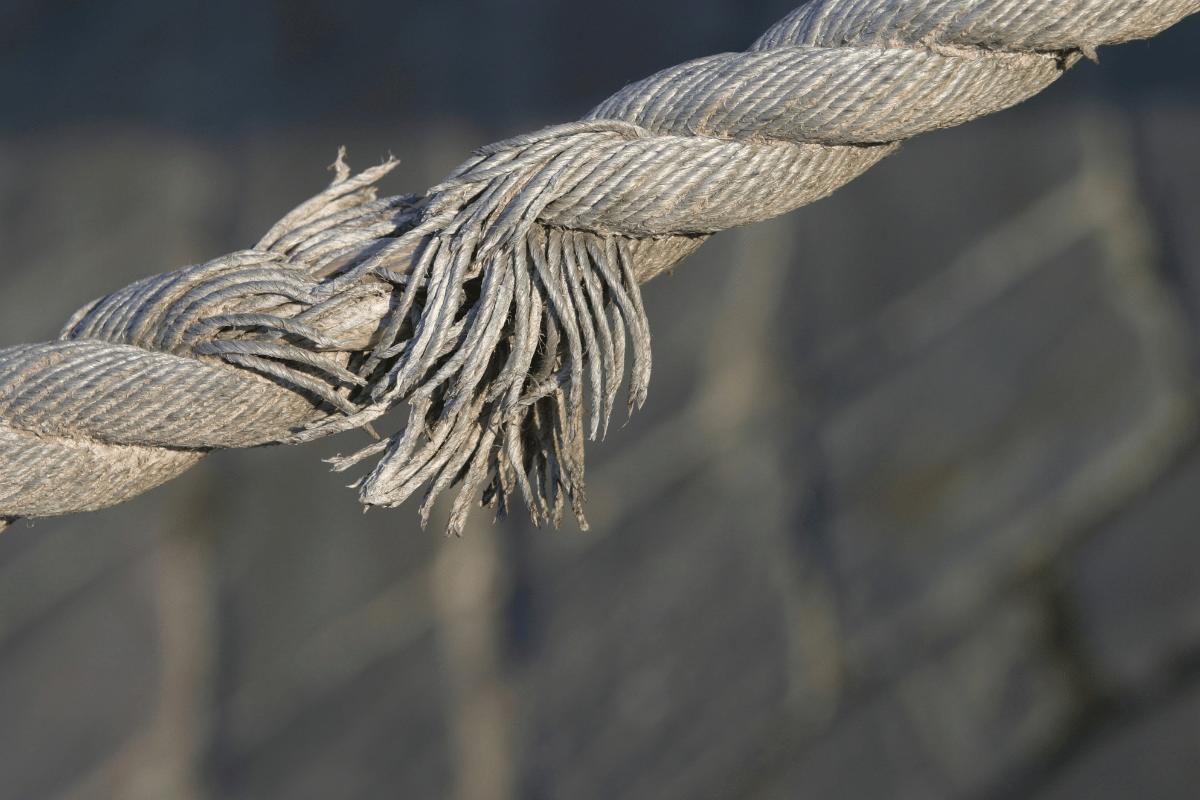

Ropes don’t usually fail out of nowhere. Most of the time, they give you plenty of warning first. Frayed fibers, flat spots, stiffness, fading, or that weird crunchy feeling when you bend them. The problem is, a lot of people ignore those signs until the rope finally gives up, and when it does it can be dangerous.

Whether you’re rigging trees, pulling wire, tying up boats, setting sail, or towing, rope inspection should be part of your regular routine. A good rope is a workhorse, but every rope has a lifespan. Knowing when to replace it can save you money, equipment, and possibly your life.

This guide walks you through a rope inspection checklist for the most common rope applications, using plain language and practical advice. Find your application and you’ll know just what to look for, what matters, and when it’s time to retire a rope.

Arborist Rope Inspection for Negative Rigging

Negative rigging puts extreme stress on a rope. When a heavy limb drops and the rope has to absorb the shock load, every fiber inside that rope takes a beating. Even if it looks fine on the outside, the internal damage can be significant.

A rope used for negative rigging should feel firm, round, and consistent along its entire length. If you run your hand down the rope and feel soft spots, flat areas, or sections that feel thinner than the rest, that rope has already lost strength. Glazing on the surface is another red flag. That shiny, melted look comes from friction heat and means the fibers have been weakened.

Pay attention to stiffness too. If the rope feels unusually stiff in certain sections, the fibers may have been heat damaged or crushed under load. Also check for sheath separation, where the outer braid shifts or bunches up over the core. That tells you the internal structure has been compromised.

If a rigging rope has taken repeated heavy drops, shows glazing, feels inconsistent, or has visible core exposure, it is time to replace it. Negative rigging is not the place to gamble on worn equipment.

Arborist Rope Inspection for Positive Rigging

Positive rigging still loads the rope, but without the hard shock of free-falling wood. Even so, wear builds up over time from friction, tension, and environmental exposure.

A healthy rope should maintain its round shape and flexibility. If it starts to feel flat, stiff, or lumpy, the internal fibers are breaking down. Look for fuzzing that goes beyond light surface wear. Deep abrasion, especially where the rope runs through blocks or around trunks, is a sign of strength loss.

Sun exposure matters too. UV damage fades rope color and weakens synthetic fibers. If your rigging rope looks washed out and brittle, it may not be safe for heavy loads anymore.

Experienced arborists who can accurately calculate SWLL may find they can get more life out of rope used for positive rigging. But when a positive rigging rope shows advanced abrasion, stiffness, UV damage, or inconsistent diameter, replacement is the smart move.

Arborist Rope Inspection for Tree Pulling

Tree pulling ropes often deal with steady tension, dirt, moisture, and ground abrasion. They might not see the same shock loads as rigging ropes, but they still wear out.

Inspect for ground damage first. Dirt and grit work their way into the fibers and act like sandpaper from the inside. If the rope feels gritty or crunchy when you bend it, internal abrasion is already happening.

Look for flattened sections from winch pressure and sharp bends. These areas weaken faster than the rest of the rope. Also check for chemical exposure. Fuel, oil, and hydraulic fluid can degrade synthetic rope fibers over time.

If the rope has stiff spots, internal grit, crushed sections, or chemical stains, it is no longer reliable for pulling trees.

Arborist Rope Inspection for Climbing

Climbing ropes are life-support equipment. There is no room for guesswork here.

A climbing rope should feel smooth, flexible, and uniform from end to end. Any soft spots, flat areas, or hard sections are signs of internal damage. Cuts, nicks, or sheath separation are immediate retirement indicators.

Pay attention to the rope ends too. Frayed or melted ends may not affect strength directly, but they suggest the rope has seen heavy wear. Also consider age. Even lightly used climbing ropes degrade over time from UV exposure and repeated loading.

If a climbing rope shows sheath damage, inconsistent feel, stiffness, or visible core, it should be replaced without hesitation.

Contractor Rope Inspection for Small Wire Pulling

Wire pulling rope takes abrasion from conduit, bends, and tight spaces. Even small jobs wear down the rope fibers.

Check for surface fuzzing that turns into broken strands. A little fuzz is normal, but deep abrasion is not. Look for flat spots where the rope has been pinched in conduit or around sharp edges.

Flex the rope and feel for stiffness or internal roughness. That gritty feeling means dirt has worked its way into the fibers.

If the rope has heavy abrasion, flattened sections, or feels rough inside, it is no longer a good choice for wire pulling.

Contractor Rope Inspection for Large Cable Pulling

Big cable pulls put serious strain on rope. High tension, heat from friction, and heavy loads can weaken even tough rope.

Look for glazing on the rope surface, which indicates heat damage. Check for stretch that does not recover. If the rope feels permanently elongated, the fibers have lost elasticity.

Inspect for diameter changes along the length. Thin spots mean fiber loss. Thick, bunched areas mean internal shifting.

When a cable pulling rope shows heat damage, permanent stretch, or uneven structure, it is time to replace it.

Boat Rope Inspection for Docking Lines

Dock lines live in the sun, salt, and water. Over time, that environment breaks down rope fibers.

Start by checking the areas that rub against cleats and pilings. These spots take the most abrasion. Look for deep fuzzing, broken strands, and thinning.

Check for stiffness caused by salt buildup or UV damage. A good dock line should still feel flexible. Also inspect for mildew and internal rot in natural or blended ropes.

If the line feels stiff, looks heavily abraded, or shows advanced UV fading, it is safer to replace it before the next storm.

Boat Rope Inspection for Mooring Lines

Mooring lines stay under constant tension and are exposed to waves, wind, and sun.

Look for stretch that does not rebound. Check for chafe damage near hardware. Feel for internal grit or hard spots caused by compression and dirt intrusion.

A mooring rope that has lost flexibility, shows heavy chafe, or feels inconsistent is no longer dependable.

Boat Rope Inspection for Sailing Lines

Sheets, halyards, and control lines need smooth handling and consistent strength.

Inspect for flattened spots where the rope runs through blocks. Look for cover wear that exposes the core. Feel for stiffness that affects knot tying and handling.

When sailing lines become hard to handle, lose their shape, or show sheath damage, performance and safety both suffer, and it’s time to replace them.

Boat Rope Inspection for Anchor Lines

Anchor lines handle heavy loads, abrasion on the seabed, and constant moisture.

Check the section closest to the anchor first. This area takes the most abuse. Look for cuts, fuzzing, and thinning. Inspect for stiffness caused by salt and UV.

If the anchor line shows deep abrasion or feels stiff and brittle, it is time for a new one before it fails under load.

Promanila Rope Inspection for Rope Railings

Promanila rope is popular for rope railings because it looks like natural manila but holds up better outdoors. Rope railings don’t usually get a lot of abuse, so they should last a long time. Even so, yearly inspection isn’t a bad idea.

Check for surface wear where people lean or rub against the rope. Look for fading from UV exposure. Feel for stiffness or brittleness that suggests long-term sun damage.

If the rope has heavy fuzzing, color loss, or feels dry and brittle, it has reached the end of its decorative and functional life.

Tow Rope Inspection for Vehicle Recovery and Towing

Tow ropes take a beating. They get yanked hard, dragged across metal and pavement, soaked, and baked in the sun. Before you trust one to pull a stuck vehicle it needs an inspection.

Start by looking for heavy abrasion. If the rope has deep fuzzing, broken strands, or thin spots from rubbing on bumpers or frames, it has already lost strength. Run your hands along the rope and feel for stiff, flat, or hard sections. Those areas usually mean the internal fibers have been crushed or heat damaged from hard pulls.

Check the ends and attachment points closely. This is where tow ropes fail most often. Frayed loops, worn splices, or knots that have been loaded under tension weaken the rope fast. If the rope looks stretched out and does not spring back, it is no longer safe for recovery work.

Sun exposure matters too. A badly faded, dry, or brittle rope has likely been weakened by UV damage.

If your tow rope shows heavy wear, stiffness, damaged ends, or serious fading, replace it. A failed tow rope can snap with dangerous force, and that is not something you want to be standing near.

Utility Rope Inspection for General Use

Utility ropes get used for everything from hauling gear to tying down loads.

Inspect for cuts, abrasion, and knots that have been loaded hard. Knots permanently weaken rope fibers, especially when used under heavy tension.

If the rope shows broken strands, flattened sections, or feels rough inside, it is no longer trustworthy for serious work.

How Long Does Rope Last

Rope lifespan depends on use, exposure, and load history. A lightly used indoor rope can last many years. A heavily used outdoor rope under constant load might need replacement in months.

Sun, heat, dirt, moisture, chemicals, and shock loads all shorten rope life. The more demanding the job, the more often the rope should be inspected.

Can You Repair a Damaged Rope

Small cosmetic fraying on the surface is normal. Structural damage is not repairable. If the core is compromised, the rope is done.

You can cut off damaged ends, but you cannot restore lost strength in the middle of a rope.

Why Regular Rope Inspection Matters

Rope failure is rarely subtle. When it breaks, it usually does so violently. Loads drop. Equipment gets damaged. People get hurt.

Regular rope inspection helps you catch problems early, plan replacements, and avoid dangerous surprises.

When in Doubt, Replace It

If you are unsure about a rope’s condition, the safest choice is to replace it. Rope is cheaper than medical bills, damaged equipment, or lost time.

A good rope should inspire confidence, not second-guessing.

Final Thoughts on Rope Safety and Replacement

Ropes work hard, and eventually, they wear out. Knowing what to look for makes all the difference. Whether you are climbing trees, pulling wire, docking boats, or towing a vehicle, inspection should be part of the job.

Strong ropes start with good materials, but safety comes from smart use, proper care, and timely replacement. Keep an eye on your gear, respect its limits, and it will keep working for you when you need it most.