Rope Safety: Understanding Breaking Strengths, SWLL, Proper Use, Rope Maintenance and More

Estimated 0 min read

Rope is one of those tools many folks grab without a second thought. But the truth is there’s a right way and a wrong way to use rope. In heavy use situations like tree work, construction, electrical, towing, and rigging, rope failure can cause serious injuries and major equipment damage. Using rope safely isn’t complicated, but it does require understanding the basics: breaking strengths, working load limits, shock loads, proper use and maintenance, and choosing the right rope for the job. When you know what your rope can and can’t handle, you work safer, faster, and with a whole lot more confidence.

Breaking Strength vs. Safe Working Load Limit

One of the most important parts of rope safety is understanding the difference between tensile strength and working load limit. The Breaking Strength, or tensile strength, is the force needed to break a new piece of rope under perfect conditions. Safe Working Load Limit, on the other hand, is the safe amount of weight the rope can handle during real-world use, without sustaining damage. If you stay at or under the SWLL you have a much lower chance of a break, which means a much lower chance of an accident.

Typically your SWLL (or WLL) will be the Breaking Strength of the rope divided by 5. This is called the safety factor, and the more dangerous the use case for the rope, or the less ideal the use of the rope, the higher the safety factor should be. For example, a 1 inch piece of HMPE rope has a breaking strength of 110,000 lbs., but for a low-danger operation its Safe Working Load Limit is up to 22,000 lbs (110,000 divided by 5).

For operations where a rope failure would be catastrophic, such as causing certain injury or death, a safety factor of 12 should be used. For this high risk operation, the same piece of HMPE now has a SWLL of 9,166 lbs (110,000 divided by 12). Finally, that same piece of HMPE being used for a low-risk operation but with a figure-eight knot on a bight (non-ideal use of the rope) should have a safety factor of more like 7, putting SWLL at 15,700 lbs.

Knowing how to calculate your safety factor and SWLL takes some experience, the ability to recognize real-world physics, and the history of your rope. Read on to learn more situations that may weaken your rope.

A final important thing to remember about SWLL is that exceeding the SWLL may weaken or damage the rope, often in ways that are not immediately obvious. The more often you exceed the SWLL, the easier it will be to break the rope. Respecting the working load limit is one of the most reliable ways to avoid accidents and get the most our of your gear.

Shock Loading and Stretch

Shock loading is one of the biggest threats to rope integrity and one of the most misunderstood. A steady pull on a rope is usually safe if it’s within the working load limit. But a sudden, jerky load can multiply the actual force on the rope. A line that could normally hold a thousand pounds might snap instantly if shock loaded with half that. This is common in towing when someone tries to yank a stuck vehicle free or in tree work when a falling limb suddenly tightens the rope.

Certain ropes are built to sustain these kinds of shocks. Many arborist rigging and bull ropes have a high stretch, meaning they are more capable of absorbing those sudden drops or stops. It doesn’t mean they’re invulnerable though! For arborists, negative rigging (securing the load below the load, so the load falls before being stopped) is assumed to exert 11x the normal force of the load. So a 300 lb branch should be negatively rigged with a rope with a SWLL of at least 3,300 lbs in order to not weaken the rope.

Be sure that if you plan on applying sudden force to a rope, that the rope has some ability to stretch and a WLL well beyond the force you plan on exerting on it. In a situation like towing a vehicle, always try to apply steady tension to the vehicle, not allowing for any slack or sudden acceleration. Take good care of your rope and it will take good care of you.

Abrasion and How It Weakens Rope Over Time

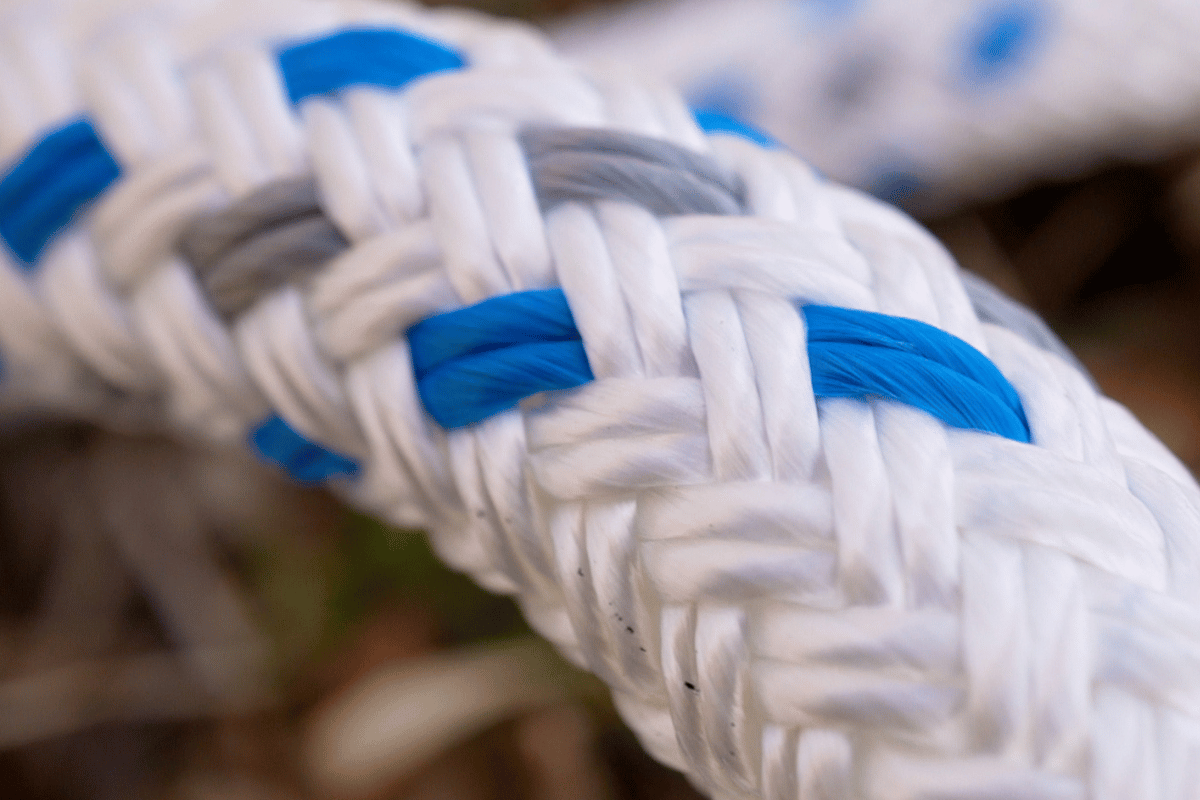

Abrasion is another major cause of rope damage. Whenever rope rubs across bark, metal, concrete, rock, roofing, or sharp edges, fibers begin breaking down. Abrasion not only wears the outside of the rope but also generates heat, which causes even more damage. Even high-strength synthetic ropes are vulnerable to this. If you notice rough spots, fuzziness, flattened areas, melted fibers, or exposed core, the rope has already been compromised. Safe rope use means padding sharp edges, using pulleys or blocks when possible, and regularly checking high-friction sections for early signs of damage. A rope may look fine at a glance but fail under load if the internal fibers are worn out.

If you know abrasion will be part of your use case, look for a rope with high abrasion resistance, like TreeBLITZ with its tightly braided polyester outer jacket. Most ropes with good abrasion resistance have a strong inner core made of something like nylon or polyolefin and an outer jacket that can handle some abrasion. Regardless of the construction, abrasion will wear on the rope so keep a close eye on ropes that are regularly used in this way.

Heat: Rope’s Silent Enemy

Heat is a rope killer, and most people don’t realize how quickly it can build up. Nylon melts at around 450°F, polyester at about 500°F, and HMPE (known for its incredible strength) melts at only about 300°F. That may sound hot, but introduce a source of friction and tension and those temperatures aren’t that difficult to reach. Quick friction through a pulley, dragging rope over a roof edge, or letting a winch line run too fast can produce enough heat to glaze or melt fibers in just seconds. Heat damage usually appears as shiny, hard, or brittle sections of rope. Once rope gets hot enough to change texture, it's no longer structurally sound. Avoiding excessive friction, using correctly sized pulleys, and handling rope smoothly are key parts of safe rope use.

Chemical Exposure and Environmental Factors

Job sites often expose rope to chemicals like oils, fuels, solvents, paints, or battery acid. Many chemicals weaken synthetic rope fibers significantly. Nylon is particularly sensitive to acids. Polyester handles chemicals best, but even it has limitations. UV damage from sunlight is another major factor, especially for ropes stored outdoors or used frequently in bright conditions. Over time, UV rays weaken the fibers and reduce strength, even if the rope looks normal. Keeping rope away from harsh chemicals, cleaning it when needed, and storing it out of direct sunlight all contribute to long-term rope safety.

Choosing the Right Rope for the Task

Rope safety begins with selecting the right rope for the job. Nylon rope offers great strength and stretch, making it suitable for dynamic loads where shock absorption matters. The most common use for nylon ropes is as boat lines, where constant waves can put it’s stretch to good use. Polyester rope provides high strength, low stretch, excellent UV resistance, and great durability, which is why it’s often the best choice for rigging, arborist work, and many contractor applications like Wire Pulling. HMPE ropes deliver extremely high breaking strength and minimal stretch, which makes them perfect for winching, heavy-duty towing, and lifting. Natural fibers like manila have excellent grip and visual appeal but degrade faster and lose strength when wet or exposed to UV. Understanding these characteristics ensures you’re working with rope that matches your task, reducing the risk of failure.

How Knots and Splices Affect Rope Strength

Many rope users don’t realize that knots reduce rope strength significantly. A bowline or clove hitch can reduce breaking strength by about 40%. Certain knots can reduce strength by up to 60%! Knots create sharp bends and friction points that concentrate stress on the rope fibers. Some knots slip under load, and others can jam so tightly that they damage the rope permanently. The best knot you can use is a figure-eight knot, which only reduces the strength of the rope by about 25%. Make sure if you are using any knots that you factor that in to your SWLL, increasing the safety factor by a representative amount.

In heavy rigging, lifting, and towing, splices are much safer because they preserve most of the rope’s original strength. A well-made eye splice maintains eighty-five to ninety-five percent of the rope’s strength, especially when paired with a thimble to maintain proper bend radius. Rope safety means knowing which knots to use, when a splice is the better option, and how different tying methods affect load capacity. If you have doubts about your ability to calculate the proper SWLL, speak with a seasoned professional, and err on the side of caution.

The Importance of Bend Radius

Bend radius plays a huge role in how much load a rope can handle safely. Rope loses strength when it bends sharply, especially around small-diameter hardware or edges. Running rope over a tiny hook, a narrow ring, or an undersized pulley puts excessive stress on the fibers right at the bend point. As a general rule, the diameter of whatever the rope is bending around should be at least four to eight times the rope’s diameter, with larger being safer. Using proper hardware not only extends the life of the rope but also prevents unexpected failures during lifting, pulling, or lowering.

Never Skip Inspection

Before any job, whether it’s a big removal, a simple pull, or a towing situation, rope inspection is non-negotiable. Safe rope use means running the rope through your hands and checking for soft spots, stiff areas, cuts, glazing, discoloration, flat sections, or exposed core fibers. Rope should feel consistent from one end to the other.

If the rope has been shock loaded, even once, internal damage may be present even if the outside looks clean! Retiring damaged rope early may feel wasteful to some folks, but it’s far cheaper and safer than dealing with the consequences of rope failure. In the trades, nothing gets overlooked more often than rope inspection, yet nothing prevents accidents more effectively.

Maintenance and Proper Storage

Rope maintenance is straightforward but essential. Rope should be kept clean, dry, and coiled or stored neatly. Dirt acts like sandpaper inside the fibers, gradually weakening the rope each time it flexes. A simple wash with water and mild soap keeps it in good condition. Leaving rope wet for long periods can encourage mildew in natural fibers, and UV exposure slowly erodes synthetic strength. Storing rope in a bucket, rope bag, or sealed container helps keep it out of the sun and away from chemicals or sharp objects. Good storage habits extend the life of the rope and improve safety on every job.

Understanding Rope Behavior in Real-World Conditions

Rope weakens over time, even with perfect storage and careful use. Every lift, pull, knot, bend, and rub takes a little life out of the rope. This doesn’t make rope unreliable; it just means rope safety requires attention and respect.

The more you understand about how rope behaves; that is, how it stretches, how it reacts to heat and friction, how knots change its strength, and how wear gradually builds up; the better equipped you are to use it safely. Whether you’re climbing, rigging, hauling, hoisting, towing, or pulling wire, rope is a tool that rewards careful handling and proper technique.

Stay Safe Out There

Rope safety isn’t complicated, but it does require understanding the basics and applying them consistently. Knowing your breaking strengths and working load limits, choosing the right rope material, avoiding shock loads, protecting the rope from abrasion and heat, storing it properly, and inspecting it regularly all go a long way toward keeping workers safe and equipment intact.

In any trade that relies on rope, whether it’s arborists, construction, electrical, towing, or mechanical work, these principles create a safer and more efficient job site. When you treat rope with respect, it pays you back with reliability you can count on day after day.