Arborist Throw Weights

Best All-Around Arborist Bull Rope: AllGear's Husky Bull Ropes are the best all-around arborist bull ropes, as they are the strongest in our product line and offer the best durability (with the urethane coating as well as polyester jacket). The nylon core allows some shock-loading as well. For all these factors combined, high-strength, extra abrasion resistance, and ability for shock-loading, we feature this rope as the best all-around arborist bull rope.

Handling and Performance: AllGear’s Husky Bull Ropes are composite rigging lines and are excellent for arborist work, and can be used in a knotless rigging system. All Gear's Knotless rigging systems allow for multiple branches to be cut and lowered simultaneously, saving you time and energy. The exterior is a double braid polyester jacket with a nylon core. These ropes have a Husky Urethane coating which provides excellent resistance to abrasion. The diameters are color-coded for quick size recognition.

Alternate Arborist Bull Ropes:

For other ropes with a polyester jacket and a nylon core (no urethane coating and not as strong as Husky):

Watch our 2 minute video for more guidance on how to choose the right rigging rope for your tree work.

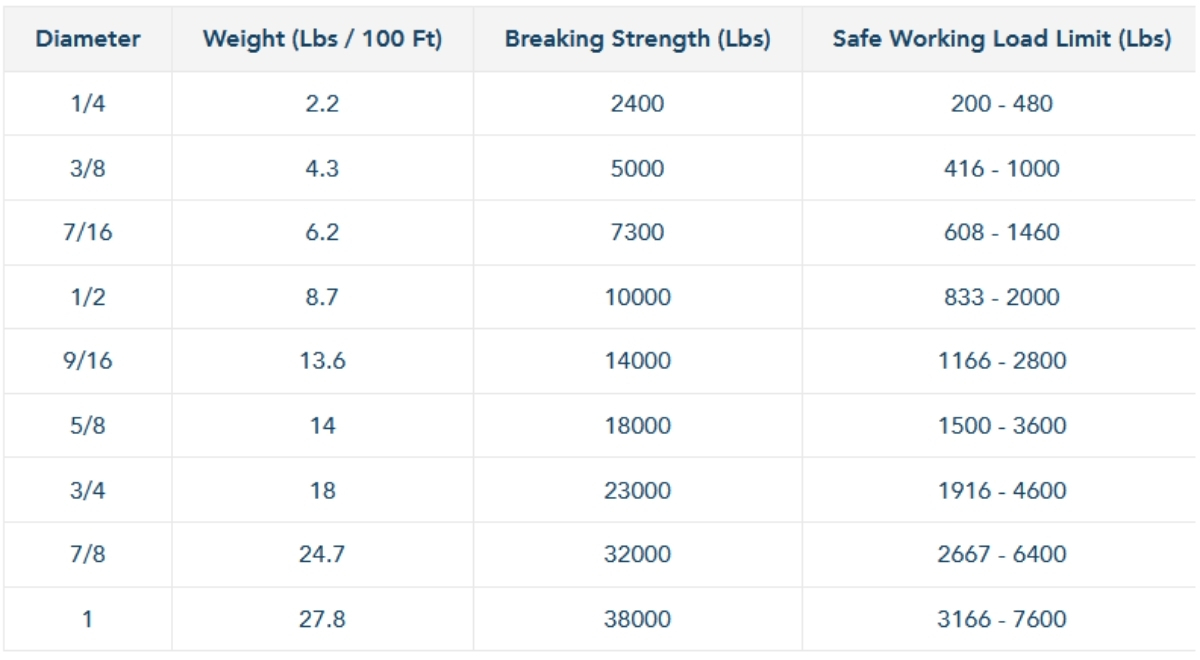

We recommend a 5:1 safety factor to determine the rated capacity or working load limit. To find the working load limit, divide the tensile strength by 5 for the diameter you choose. See specifications for tensile strength and working load limits (WLL). Do NOT exceed the working load limit.

One of the most important parts of rope safety is understanding the difference between tensile strength and working load limit. The Breaking Strength, or tensile strength, is the force needed to break a new piece of rope under perfect conditions. Safe Working Load Limit, on the other hand, is the safe amount of weight the rope can handle during real-world use, without sustaining damage. If you stay at or under the SWLL you have a much lower chance of a break, which means a much lower chance of an accident.

Typically your SWLL (or WLL) will be the Breaking Strength of the rope divided by 5. This is called the safety factor, and the more dangerous the use case for the rope, or the less ideal the use of the rope, the higher the safety factor should be. For example, a 1 inch piece of HMPE rope has a breaking strength of 110,000 lbs., but for a low-danger operation its Safe Working Load Limit is up to 22,000 lbs (110,000 divided by 5).

For operations where a rope failure would be catastrophic, such as causing certain injury or death, a safety factor of 12 should be used. For this high risk operation, the same piece of HMPE now has a SWLL of 9,166 lbs (110,000 divided by 12). Finally, that same piece of HMPE being used for a low-risk operation but with a figure-eight knot on a bight (non-ideal use of the rope) should have a safety factor of more like 7, putting SWLL at 15,700 lbs.

Knowing how to calculate your safety factor and SWLL takes some experience, the ability to recognize real-world physics, and the history of your rope. Read on to learn more situations that may weaken your rope.

A final important thing to remember about SWLL is that exceeding the SWLL may weaken or damage the rope, often in ways that are not immediately obvious. The more often you exceed the SWLL, the easier it will be to break the rope. Respecting the working load limit is one of the most reliable ways to avoid accidents and get the most our of your gear.

Many rope users don’t realize that knots reduce rope strength significantly. A bowline or clove hitch can reduce breaking strength by about 40%. Certain knots can reduce strength by up to 60%! Knots create sharp bends and friction points that concentrate stress on the rope fibers. Some knots slip under load, and others can jam so tightly that they damage the rope permanently. The best knot you can use is a figure-eight knot, which only reduces the strength of the rope by about 25%. Make sure if you are using any knots that you factor that in to your SWLL, increasing the safety factor by a representative amount.

In heavy rigging, lifting, and towing, splices are much safer because they preserve most of the rope’s original strength. A well-made eye splice maintains eighty-five to ninety-five percent of the rope’s strength, especially when paired with a thimble to maintain proper bend radius. Rope safety means knowing which knots to use, when a splice is the better option, and how different tying methods affect load capacity. If you have doubts about your ability to calculate the proper SWLL, speak with a seasoned professional, and err on the side of caution.

FAQ's Husky Arborist Bull Rope

Question: How do I choose the color I want of the Husky Arborist Bull Rope?

Answer: Each diameter of the Husky Arborist Bull Rope is a different color so you can quickly identify each rope. Due to this color-coding system for this product, each diameter only comes in one color.

Question: Do the Husky Arborist Bull Ropes come in any other colors?

Answer: The Husky Arborist Bull Ropes are color-coded by diameter and are the only available colors.

| Diameter | Weight (Lbs / 100 Ft) | Breaking Strength (Lbs) | Safe Working Load Limit (Lbs) |

|---|---|---|---|

| 1/4 | 2.2 | 2400 | 200 - 480 |

| 3/8 | 4.3 | 5000 | 416 - 1000 |

| 7/16 | 6.2 | 7300 | 608 - 1460 |

| 1/2 | 8.7 | 10000 | 833 - 2000 |

| 9/16 | 13.6 | 14000 | 1166 - 2800 |

| 5/8 | 14 | 18000 | 1500 - 3600 |

| 3/4 | 18 | 23000 | 1916 - 4600 |

| 7/8 | 24.7 | 32000 | 2667 - 6400 |

| 1 | 27.8 | 38000 | 3166 - 7600 |

Strength

Stretch

Durability

Abrasion Resistance

Rot Resistance

Sunlight / UV Resistance

Petroleum Resistance

Mold / Mildew Resistance

Loading results...